News

CERAMITEC 2024 – Munich

CERAMITEC is the international leading trade fair for the ceramics industry.

As an event “CERAMITEC” is THE meeting point of the main producers and users as everything revolves around the material of the future.

OMS Group will participate in this edition and show important news!

You can’t miss this date. Stay tuned!

From 9 and 12 April 2024, our Sales staff will be glad to welcome you in Hall A4 – Booth 321

More details: https://ceramitec.com/en/munich/good-reasons-to-visit/

APPEX2024 – MELBOURNE

APPEX 2024 – Australasia’s Processing and Packaging Expo is an exhibition that will truly represent all sectors of the industry.

More than “just a packaging-only exhibition”, APPEX is a show aimed at encompassing the total processing and packaging sector, including machinery, ancillary equipment, material and packaging, food processing and industry services.

It will provide a comprehensive range of all processing and packaging equipment and services under one roof.

OMS Australasia and OMS Group will attend at this edition, presenting the latest news suitable to satisfy the multiple needs of the packaging sector.

“You can’t miss this appointment!”

Between 12 and 15 March, 2024 our Sales staff, will be glad to welcome you at: Booth A045

More details: https://www.appex.com.au

LIGNA2023 – Hannover

As the world’s leading trade fair with a global impact, LIGNA places itself at the service of the woodworking and wood processing industry. The fair will have a strong focus on the “Future” that belongs to those involved in the “transformation of woodworking”, “prefabrication processes in timber construction” and “process technologies for the bioeconomy”.

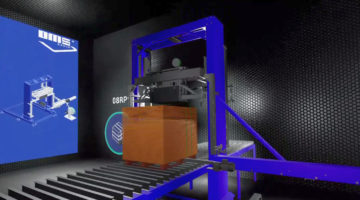

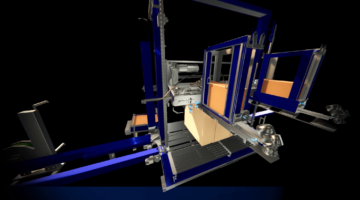

OMS Group will attend at this edition, presenting a packaging machine suitable for satisfying the many needs of the wood sector and an innovative “virtual” showroom!! You can’t miss this appointment!

Between 15 and 19 May, 2023 our Sales staff, will be happy to welcome you at

Hall 26 – Booth E08

More details: https://www.ligna.de/en/

INTERPACK2023 Düsseldorf

INTERPACK 2023 is the global trend-setter for the future themes of the industry. From sustainability to digitalisation: what will be reality tomorrow is presented here today.

When the global packaging industry meets in Düsseldorf, when innovations along the entire value chain are presented and the top trends are discussed, then you know it’s INTERPACK. The focus is on packaging materials, packaging machines and related process technology for the food, beverage, confectionery, bakery, pharmaceutical, cosmetics, non-food and industrial goods sectors. This is what makes INTERPACK simply unique!

OMS Group will attend at this edition, presenting the latest news suitable to satisfy the multiple needs of the packaging sector and an innovative “virtual” show room”!!

“You can’t miss this appointment!”

Between 4 and 10 May, 2023 our Sales staff, will be happy to welcome you at

Hall 12 – Booth C77

More details: https://www.interpack.com/

LOGIMAT2023 – STUTTGART

A top event for in-company material flow and computer-controlled processes from procurement to production and distribution…in the heart of Europe.

LogiMAT, the International Trade Fair for Intralogistics Solutions and Process Management, sets new standards as the biggest annual intralogistics exhibition in Europe. This is the leading international trade fair that provides a comprehensive market overview and competent knowledge-transfer.

OMS Group will attend again at this important event, with an automated line solution and other news!!

Between 25 and 27 April 2023, our Sales staff, will be happy to welcome you at:

Hall Nr.2 – Booth 2B41

More details: https://www.logimat-messe.de/en

CCE 2023 – Munich

The CCE – International Corrugated & Carton Exhibition – in Munich is the international European trade fair for the corrugated and folding carton industry.

Many companies attend to get the latest product, designs and innovations for the industry and present the latest technologies and trends. It is an excellent opportunity for buyers and suppliers to meet and conduct business.

OMS Group will participate in this edition and show important news!

You can’t miss this date. Stay tuned!

From 14 and 16 March 2023, our Sales people, will be happy to welcome you at Hall B6 – Booth 2230

More details: https://www.cce-international.com/

ALL4PACK2022 – Paris

ALL4PACK2022 – PARIS

Building tomorrow’s world today: this is the challenge we face daily.

ALL4PACK is the go-to trade fair for the innovative and sustainable packaging solutions offers to the visitors a thoroughly comprehensive package. Packaging, processing, printing and logistics: these four areas of expertise cover all industry needs.

OMS Group will be attend at this edition, together with its French distributor GETRA S.a.s., to present its novelties! Don’t miss this appointment. Stay tuned!

From 21 till 24 Novembre, our Sales staff will be happy to welcome you at:

Hall 5A – Booth E137

More details: https://www.all4pack.com/

BAUMA2022 -MONACO dI BAVIERA

BAUMA is the worldwide platform of construction industry.

The global industry in one place: BAUMA is the most important meeting place for companies involved in construction machinery, building material machinery, mining machinery, construction vehicles and equipment. As leading platform, it provides a complete market overview in its full spectrum.

OMS Group will attend at this edition and present important news! Do not miss this appointment. Stay tuned!

Between 24 and 30 October, our Sales staff, will be happy to welcome you at:

Hall C1 – Booth 438

More details: https://bauma.de/en/

TECNA2022 – RIMINI

TECNA 2022 The international exhibition of technologies and supplies for surfaces

THE INTERNATIONAL HUB FOR DEVELOPMENT OF SURFACES.

TECNA is a global platform that attracts key industry players from around the world, in search of greater competitiveness and production efficiency, the latest trends and the most advanced technological innovations for decoration and design, large formats, full digital, environmental sustainability.

Most of buyers will come from: Asia, Middle East, Africa, the Mediterreanean Area, Europe and Latin America.

OMS Group, as usual, will attend at this edition and present important news! Do not miss this appointment. Stay tuned!

Between 27 and 30 september, our Sales staff, will be happy to welcome you at:

Hall D1 – booth 008

More details: https://en.tecnaexpo.com/

GLASSTEC – DÜSSELDORF

GLASSTEC International – HOT SPOT FOR SUCCESS!

GLASSTEC sets new standards in every respect.

With a focus on the top growth markets in the glass industry, here the trends are set that will move the future. This event is industry’s leading meeting place and showcase for technical developments and the absolute worldwide hot spot.

OMS Group will attend at this edition and present important news! Do not miss this appointment. Stay tuned!

Between 20 and 23 september, our Sales staff, will be happy to welcome you at:

Hall13 – booth F64

More details: https://www.glasstec-online.com/

IPACK-IMA 2022 – MILANO

IPACK-IMA is the exhibition organized by Ipack Ima Srl, joint venture between UCIMA and Fiera Milano.

It has strongly established itself as a specialized meeting point in Europe, for processing and packaging, thanks to the partnership between the leading European trade fair operator and the industry association of reference for the sector, with a strong strategic value.

The shows also leverage UCIMA’s international relation network as well as the planning and operational support provided by its member companies, giving rise to specialized events in line with the expectations of international clients.

OMS Group will attend in this edition, the first after the long post-pandemic period, ensuring compliance with the rules imposed by the contingent situation.

We will present important news! You cannot miss this appointment. Stay tuned!

Between 03 and 06 May 2022, our Sales staff will be happy to welcome you at:

Hall 6 – Booth A17 / B18

More details: https://www.ipackima.com/

CCE 2022 – Munich

CCE International it has firmly established itself as a specialized European meeting point for this industry.

This fair is focusses solely on manufacturing and converting corrugated and cartonboard.

CCE International is a unique platform to present our most up-to-date machines and technologies to a specialized public who intends to improve their production processes and find practical solutions to implement new product ideas.

OMS Group will participate in this edition, the first after the post-COVID period, ensuring compliance with the rules imposed by the current situation.

We will present important news! You cannot miss this appointment. Stay tuned!

Between 15 and 17 March 2022, our Sales staff, will be happy to welcome you at Hall A4 – booth 2246

More details: https://www.cce-international.com/2021/english/

OMG Group & LAPP

A “wired” collaboration for success

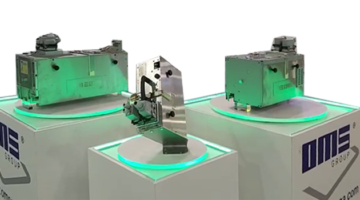

End-of-line packaging is an essential operation for the safe handling and transport of products. Efficiency, flexibility and precision are the requirements that modern secondary packaging systems must meet in order to ensure maximum productivity levels, even in the last operational phases of the supply chain.

OMS Group, a world player in the production of systems for the packaging of palletized products, is perfectly aware of this, which for over 20 years has relied on LAPP, a leader in the development and production of integrated solutions in connection and wiring technology, for the wiring of the various types of machines that make up its offer.

“The quality and reliability of LAPP products are certainly the pillars on which our consolidated relationship is based” comments Maurizio Alessi, OMS Marketing Manager who continues “Furthermore, knowing and using LAPP cables for so long has allowed us to implement scale economies in order to optimize the design of our machinery, in terms of electrical components, according to their specific characteristics “and concludes” From this point of view, the easy availability on a global scale represents for us, as International group, one of the main advantages together with the wide UL and CSA certified range for the North American market “.

“OMS & LAPP” are two international companies which share the idea that developing custom solutions is a real added value for their customers, state Gaetano Grasso, Head of Product Management and Marketing of LAPP, who adds” This is the premise of our a relationship that also includes supporting OMS in the design and construction of highly performing end-of-line packaging machines “and concludes” For this reason, in the selection of the ideal supplier for the packaging of the cable reels of the new logistics center of Hanover, LAPP Germany has relied on the validity of the personalized proposals of OMS ”.

A partnership based on excellence and mutual collaboration, also evidenced by the choice by LAPP to adopt OMS solutions for its new logistics center in Hannover.

“Thanks to its expertise, OMS-IPS (German branch of OMS Group) was able to configure and install our” dream machine “which combines, in a single workstation, both strapping (08RP model) and operations for hood, with shrink film (AT53 model), thus allowing us to reduce the use of film, where permitted “says Andreas Gesse, Head of Logistics Center 3 in Hannover, of LAPP Germany who continues” A solution that allows you to package products with a diameter of up to 120 cm, with a speed of 80 packs per hour, double compared to the machines used previously “and concludes” Finally, given the particularly delicate historical period, it acquires even more value that they have strictly respected delivery times, in addition to the timeliness of local technical assistance service “.

OMS GROUP a matter of packaging.

YOUR BEST SOLUTION FOR THE BIG SIZES

NEW STRAPPING SYSTEM

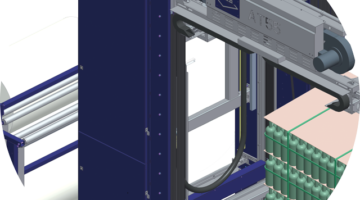

Our distributor, Gordian Strapping, has supplied a new vertical plastic strapping machine and slat conveyor to Wienerberger at their plant in Ewhurst.

Wienerberger is the world’s largest producer of bricks, and the No. 1 producer of clay roof tiles in Europe, with 229 plants in 27 countries.

The Ewhurst factory required a new strapping machine to replace an ageing system that had reached the end of its working life. The site also needed a new slat conveyor underneath the stretch hooding machine to replace the previous conveyor that had not proven to be robust enough for the demanding environment of a clay brick factory.

Gordian installed an OMS TS300 vertical strapping machine, equipped with the latest generation TR2000 strapping head, along with a test rig and a spare strapping head. The spare head can be introduced into the line in the event of a breakdown, or to allow production to continue while another head is serviced off-line on the test rig.

The OMS TR2000 Head, which can apply a max. tension of 7000N (700kg) is designed for use with Polyester Strapping (PET) and is proven through- out the building products industry. It features quick-change modular parts that can be swapped out within 5 minutes in the event of a fault, there- by minimizing downtime. Heat Seal technology means that the head can be quickly adjusted to suit different strap specifications, and a major service is only required every 200,000 cycles. The strapping machine is equipped with an OMS PBTR Turntable Jumbo Strap Dispenser holding 7 coils of strap. With 4,500m of strap on each coil, rather than 1,500m on a standard coil of strap, downtime due to coil changes is kept to a minimum.

Gordian is as an existing supplier to Wienerberger with a proven track record of installing and maintaining strapping and stretch hooding equipment. With 16 highly trained service engineers based across the UK, Gordian is well placed to offer after sales service and support.