Case History

OMG Group & LAPP

A “wired” collaboration for success

End-of-line packaging is an essential operation for the safe handling and transport of products. Efficiency, flexibility and precision are the requirements that modern secondary packaging systems must meet in order to ensure maximum productivity levels, even in the last operational phases of the supply chain.

OMS Group, a world player in the production of systems for the packaging of palletized products, is perfectly aware of this, which for over 20 years has relied on LAPP, a leader in the development and production of integrated solutions in connection and wiring technology, for the wiring of the various types of machines that make up its offer.

“The quality and reliability of LAPP products are certainly the pillars on which our consolidated relationship is based” comments Maurizio Alessi, OMS Marketing Manager who continues “Furthermore, knowing and using LAPP cables for so long has allowed us to implement scale economies in order to optimize the design of our machinery, in terms of electrical components, according to their specific characteristics “and concludes” From this point of view, the easy availability on a global scale represents for us, as International group, one of the main advantages together with the wide UL and CSA certified range for the North American market “.

“OMS & LAPP” are two international companies which share the idea that developing custom solutions is a real added value for their customers, state Gaetano Grasso, Head of Product Management and Marketing of LAPP, who adds” This is the premise of our a relationship that also includes supporting OMS in the design and construction of highly performing end-of-line packaging machines “and concludes” For this reason, in the selection of the ideal supplier for the packaging of the cable reels of the new logistics center of Hanover, LAPP Germany has relied on the validity of the personalized proposals of OMS ”.

A partnership based on excellence and mutual collaboration, also evidenced by the choice by LAPP to adopt OMS solutions for its new logistics center in Hannover.

“Thanks to its expertise, OMS-IPS (German branch of OMS Group) was able to configure and install our” dream machine “which combines, in a single workstation, both strapping (08RP model) and operations for hood, with shrink film (AT53 model), thus allowing us to reduce the use of film, where permitted “says Andreas Gesse, Head of Logistics Center 3 in Hannover, of LAPP Germany who continues” A solution that allows you to package products with a diameter of up to 120 cm, with a speed of 80 packs per hour, double compared to the machines used previously “and concludes” Finally, given the particularly delicate historical period, it acquires even more value that they have strictly respected delivery times, in addition to the timeliness of local technical assistance service “.

OMS GROUP a matter of packaging.

YOUR BEST SOLUTION FOR THE BIG SIZES

NEW STRAPPING SYSTEM

Our distributor, Gordian Strapping, has supplied a new vertical plastic strapping machine and slat conveyor to Wienerberger at their plant in Ewhurst.

Wienerberger is the world’s largest producer of bricks, and the No. 1 producer of clay roof tiles in Europe, with 229 plants in 27 countries.

The Ewhurst factory required a new strapping machine to replace an ageing system that had reached the end of its working life. The site also needed a new slat conveyor underneath the stretch hooding machine to replace the previous conveyor that had not proven to be robust enough for the demanding environment of a clay brick factory.

Gordian installed an OMS TS300 vertical strapping machine, equipped with the latest generation TR2000 strapping head, along with a test rig and a spare strapping head. The spare head can be introduced into the line in the event of a breakdown, or to allow production to continue while another head is serviced off-line on the test rig.

The OMS TR2000 Head, which can apply a max. tension of 7000N (700kg) is designed for use with Polyester Strapping (PET) and is proven through- out the building products industry. It features quick-change modular parts that can be swapped out within 5 minutes in the event of a fault, there- by minimizing downtime. Heat Seal technology means that the head can be quickly adjusted to suit different strap specifications, and a major service is only required every 200,000 cycles. The strapping machine is equipped with an OMS PBTR Turntable Jumbo Strap Dispenser holding 7 coils of strap. With 4,500m of strap on each coil, rather than 1,500m on a standard coil of strap, downtime due to coil changes is kept to a minimum.

Gordian is as an existing supplier to Wienerberger with a proven track record of installing and maintaining strapping and stretch hooding equipment. With 16 highly trained service engineers based across the UK, Gordian is well placed to offer after sales service and support.

Pinguin Lutosa

Gordian Strapping LTD, our distributor in the U.K. has provided Pinguin Lutosa with a sistematic solution at their site of King’s Lynn.

Pinguin Lutosa, a leading frozen vegetable processor boasts some of the best automated packing facilities in Europe. The Kings Lynn site is a state of the art production and packing site with capacity to produce over 120,000 tonnes of product p.a. Gordian has integrated a AVR 900 automatic pallet ring wrapper into Pinguin’s packaging line.

The machine replaced an ageing rotary arm wrapper and is part of a programme of upgrades to the automated packaging facility at Kings Lynn. It was essential that the Ring Wrapper matched the footprint of the old machine and was compatible with the existing conveyor and safety systems.

It was also vital for the new machine to overcome the costly issue of loose film tails which can lead to rejection of pallets by automated warehousing systems. Rapid installation over a weekend was critical to ensure minimum disruption to the freezing of fresh vegetable produce.

Pinguin Lutosa has the AVR 900 Ring Wrappers in operation at their site in Belgium and had no hesitation in installing another machine in the UK.

A very small space available to install three strapping machines

This model of strapping machine has been purchased by an important multinational corporation of the United States.

Their first necessity was to have an implant made of two lines that could manage a very high productive performance per hour.

For this Company it was also very important to stick to all the security restrictions they had in their plant and to manage in the best way possible the limited space of the site of installation of such a complex implant.

OMS supplied an impant made of:

Three strapping machines model 082 that had two mobile strapping heads TR14HD equipped with a special device that allows to insert corner perimetral protections.

This configuration grants the maximum flexibility and productive capacity in function of the type of the product that needs to be packed.

Perimetral systems, devices and muting photocells to manage the security of the whole implant.

Centering and rotation device, transport of the pallets designed in particular according to the space available.

6,30 meters, the higher OMS machine ever made

Our distributor Gordian Strapping has provided a stretch hooder for Sheffield based timber merchants and animal bedding suppliers McClure Timber Supplies t/a Greenwood Forest Products. Standing 6300mm from the floor, it is the tallest OMS manufactured stretch hooding machine in the UK.

McClure required a stretch hooder for baled sawdust and baled wood shavings for cattle, horses and other livestock to improve presentation and pack security in transit and also to enable pallets to be stored outside without risk of water ingress. With space at a premium, a high level of engineering knowledge and ingenuity were required to find a solution that met the clients’ need with a minimum of fuss and down-time.

Gordian Strapping installed an OMS manufactured IS43 stretch hooder off the conveyor centre line because of space restrictions and incorporated a specially designed shuttle conveyor to enable the packages to be positioned correctly for hooding.

The benefits were many:

greater pack security with the product now secured firmly to the pallet,

no sideways movement in transport,

the ability to hood packs in line straight after the baler,

Improved visible pack presentation and ultimately less returns and less damage as the pack remains in exactly the same condition it leaves McClure’s. McClure’s Owner and Managing Director, Richard McClure feels the solution has been a real boon to his company.

OMS stretch hooding IS46

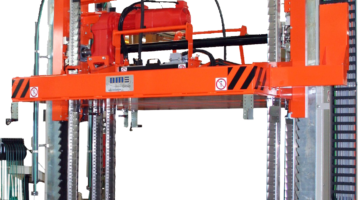

The OMS stretch hooding IS46 is an authomatic machine which can be part of an authomatized production line, it performs the packaging of the goods through bags of extensible film.

These bags can be made of different materials and they have different compositions, their main function is to protect the goods during the transport and the storage and also granting that the packaging will be stable and waterproof.

Through the use of coils of extensible tubular film it is possible to hood packs of different shapes and mesures.

During the design of the machine the main movements of the hooding cycle have been divided in 3 different phases; this choice led to the achievement of high production performances (up to 250 packs/h), always granting high quality aesthetic of the packed product.

Thank to the innovative coil-holder system it is possible to manage up to three coils at the same time, the three coils are installed at the level of the ground to enable the operator to substitute them without any downtime.

This system is designed to enable the operator to have easy access to the main parts of the machine during the maintenance and this guarantees a great saving of time which is one of the many qualities of this model of hooder.

This machine is actually one of the most performing machines of its cathegory that you can currently find on the market.

MAIN ADVANTAGES:

Performance: high productivity (up yo 250 packs/h)

Timing: no downtimes and no wasting time to change the coil

Eco-friendly: energy saving, because the film doesn’t need to be heated

Stability: the packaging with the stretch film is safer and more resistant, it also grants an high stability during the transport

Protection: the hood protects the goods from water, dust and bad weather conditions

Environment: less pollution tank to the less use of film